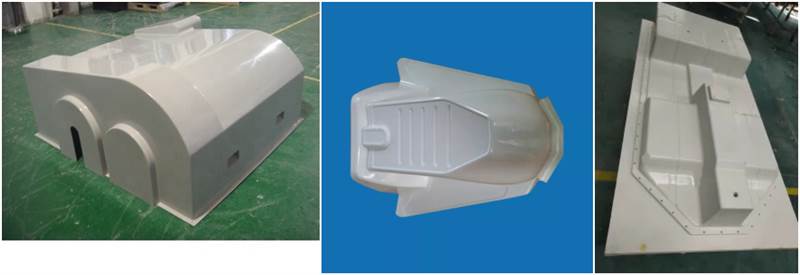

Swimming Pool moulds production in fiberglass

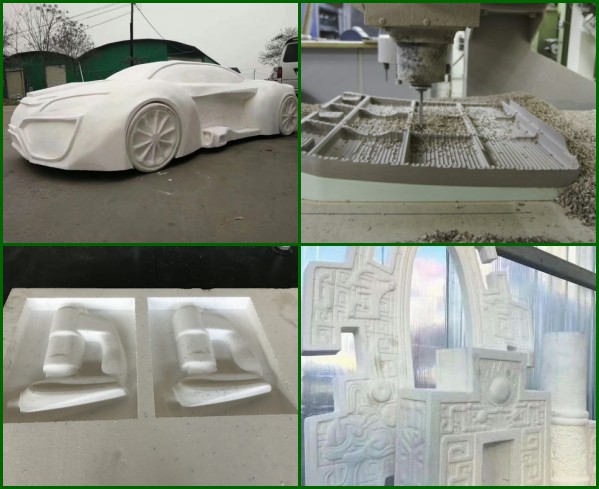

1:1 Car molds production

Boat/ Yachat/Marine molds production

Injection molding model production

Monumental Sculptures: Carving marble, wood, or metals into intricate 3D artworks.

Architectural Elements: Customized columns, reliefs, and decorative panels.Park entertainment facilities, performance props, mall decorations

Jewelry: Precision engraving of intricate patterns on precious metals or gemstones.

Turbine Blades & Engine Components: 5-axis machines carve aerodynamic profiles and cooling channels in turbine blades, ensuring optimal performance under extreme conditions.

Structural Parts: Used for machining lightweight aerospace alloys (e.g., titanium, aluminum) into wing ribs, brackets, and fuselage components.

Prototyping: Rapid production of complex prototypes for testing aerodynamic or structural designs.

Ship Propellers: Machining bronze or stainless steel propellers with hydrodynamic profiles.

Weapon Systems: High-strength components for firearms, missiles, or armored vehicles.

Submarine Parts: Pressure-resistant housings and sonar equipment.

Engine Blocks & Cylinder Heads: Precision machining of internal combustion chambers and coolant pathways.

Customized Parts: Production of high-performance components like suspension arms, gearboxes, and intake manifolds.

EV Components: Machining lightweight battery housings and motor parts for electric vehicles.

Orthopedic Implants: Customized hip/knee replacements with biocompatible materials (e.g., titanium, PEEK).

Surgical Instruments: High-precision tools with ergonomic designs, such as forceps and bone drills.

Dental Prosthetics: Crowns, bridges, and aligners milled from ceramics or resins for perfect patient fit.

Wind Turbine Components: Blades, hubs, and gearbox parts requiring lightweight yet durable designs.

Oil & Gas Valves: Machining corrosion-resistant alloy valves and drill components with intricate flow paths.

Hydropower Turbines: Profiling runner blades for maximum efficiency.

Smartphone Housings: Aluminum or composite casings with precise cutouts for buttons and ports.

Optics & Lenses: Molding inserts for camera lenses or LED light guides.

Wearables: Ergonomic designs for smartwatch cases or VR headset frames.

Working materials introduce :

1. Engineering Plastics and Composite Materials

PEEK (Polyether Ether Ketone): High biocompatibility, suitable for processing medical implants and high-temperature insulation components.

Nylon (PA): Lightweight and wear-resistant, used for manufacturing industrial components such as gears and bearings.

Carbon Fiber Reinforced Plastic (CFRP): High strength, low density, used for drone frames, racing car bodies, and aerospace structural components.

ABS: Easy to form, capable of processing electronic product casings and automotive interior prototypes.

Fiberglass : easy to mill with different molds in swimming pool etc

2. Wood and Foam

Hardwood (such as rosewood and oak): carving furniture decorations, musical instrument components, and artworks.

Engineering wood (such as plywood): making building models and exhibition props.

Polyurethane foam: rapid prototyping, used for automobile/aviation model verification.

3.Stone and Hard Materials

Marble/Granite: Carving architectural decorations, monuments, and artistic sculptures.

Glass/Ceramic: Processing optical device bases and precision ceramic parts (such as dental restorations).

Artificial stone: customized furniture countertops and bathroom products.

4. Metallic Materials

Aluminum alloy: Lightweight and easy to process, used for aerospace parts (such as aircraft structural components), automotive components (engine parts), and electronic product casings.

Titanium alloy: high-strength, corrosion-resistant, suitable for processing medical implants (artificial joints), aircraft engine blades, and high-end sports equipment.

Copper alloy: excellent thermal and electrical conductivity, suitable for processing electronic heat sinks, jewelry molds, and artistic sculptures.

High temperature alloys (such as nickel based alloys): resistant to high temperature and high pressure, used in aviation engine combustion chambers and gas turbine blades.

5. Other Special Materials

Graphite: Processing EDM (Electric Discharge Machining) electrodes for mold manufacturing.

Acrylic (PMMA): Cutting and carving of transparent parts, such as advertising light boxes and display stands.

Soft metals (such as brass, silver): precision jewelry carving, customized badges.

| 5 Axis CNC Router RSKM25-12 Quotation Sheet | |

| Model | RSKM25-12 |

| Working size | Y:17000*X:5000*Z:2000mm(in 5 axis condition) |

| Machine outside dimension | 19800*6650mm*5400mm |

| Body structure | Steel structure |

| Gantry structure | Customized strength steel welded |

| Working table | ThickSteel welded T-SLOT working table |

| X/Y/Z Working accuracy | ±0.1mm/±0.05mm |

| X/Y/Z Repositioning accuracy | ±0.1mm/±0.05mm |

| B/C rotate accuracy | - 60/20 arc sec |

| Traveling speed | 40m/min |

| Working speed | 25m/min |

| Spindle | Italy HITECO 5 axis water cooling spindle 25KW with HSK-63F ER40/DAMES L500 5 axis head |

| Spindle rotary speed | 0-24000rpm |

| 5 axis part | B axis +-135 degree/C axis +-320 degree |

| Control system | Taiwan Syntec system 5 axis 610MA-E5 with remote |

| Drive and motor | Z:JAPAN YASKAWA 4.4KW brand servo motor driver with encoder+Japan Shimpo reducer motor(ONE) X/Y:2.9KW YASKAWA servo motor driver with encoder+Japan Shimpo reducer motor(THREE) |

| Transmission mode | Z:40mm TBI ball screw &TWIN 45 square rail X:2M Helical gear rack &TWIN 45 square rail Y:2M Helical gear rack &TWIN 45 square rail |

| Working voltage | AC380V/60HZ&50hz |

| Command language | G-code,*u00,*mmg,*plt |

| Dust collector | Available |

| Oiling system | Automatic oiling |

| Machine weight | Above 10000KG |

| ATC | Linear tool changer 12 pieces |

| Package Measure | 880cm*360cm*520cm |

| Name | Quantity |

| 1.TAIWAN Syntec 610MA-E5 | 1 |

| 2.X axis YASKAWA Servo 2.9kw | 1 |

| 3.Y axis YASKAWA Servo 2.9kw | 2 |

| 4.Z axis YASKAWA Servo 4.4kw | 1 |

| 5.Italy Hiteco 25kw water cooling spindle HSK63F ER40 | 1 |

| 6.X PMI high precisiong grind 2M rack | 2 |

| 7.Y PMI high precisiong grind 2M rack | 2 |

| 8.Z PMI high precisiong ball screw 4040 | 1 |

| 9.X axis HIWIN45 square rail | 3 |

| 10.Y axis HIWIN45 square rail | 4 |

| 11.Z axis HIWIN30 square rail | 8 |

| 12. DELTA 18kw inveter | 1 |

| 13.Germany DAMES 5 axis head L500 series | 1 |

| 14.5 axis real working size 17000x5000x2000 | 1 |

| 15.Central gas storage system | 1 |

| 16.Central lubrication system | 1 |

| 17.ATC Tool holder 12 pieces | 12 |

| 18.Spring clamps and testing tools | 1 |

| 19. Separate control panel | 1 |

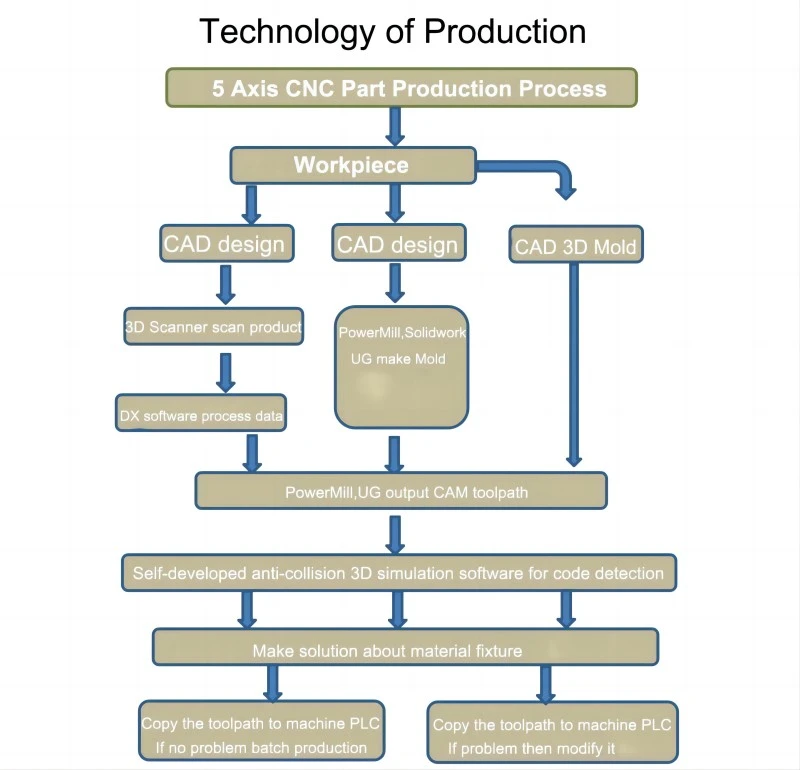

Production Process for Rhino Gantry type 5 axis cnc milling machine

HITECO and OLI air cooling/ water cooling spindle 220v/380v HSK63F/HSK63E/HSK63A holder Suitable for wood,plastic,aluminum and other composite material max power 20kw |

Ultra high precision, durable, all cast iron body |

Intelligent real-time voltage and temperature display in 5 axis cnc router machine system |

Stepladder along with machine height and width, more convenient for machine inspection and maintenance |

X axis of 5 axis cnc router is with 3 rows square rail HIWIN45/PMI45 and each rail equipped with 3 blocks. |

Z axis high precision TBI 40MM ball screw for transmission Z axis high precision TBI 40MM ball screw for transmission |

5 axis syntec system romote handle suitable for large working size table |

PLC CNC system: 5 axis Syntec 610MA-E5 with separate control panel,working perfectly with YASKAWA M3 servo motor drivers,support RTCP 5 axis function that can complete high-precision curved surface maching. |

This is Syntec system's handle wheel. It is portable so you can bring it very near of machine to check detail working of XYZAB four axis |

Vacuum table with 7.5kw air cooling vacuum pump + T-SLOT combination Linear tool changer 12 pcs (max 20 pcs can be fixed) |

High quality automatic tool sensor instrument to adjust the distance between tool point and material |

Central gas storage system on top machine z axis to supply sufficient and stable gas for machine |