By Serena Zhang | 16 November 2023 | 1 Comments

How to Build a Model Boat ? (Detailed Guidance)

How to Build a Model Boat ? (Detailed Guidance)

When talking about ship /boad/yacht models, many people will think of such models like decoration or hand-made models small size.

In fact, there is also a ship model in the manufacturing industry with big size, which is mostly processed with foam and wood. Today we are talking about this type of boat models.

This boat ship model or yacht foam model is mainly processed by a 5 axis machining center. Yacht foam models are usually made of foam materials such as polyurethane or polystyrene, which can be cut and carved through a 5 axis machining center.

And this kind of models usually dimension is big like 5ftx10ft/20ft x 40ft/10ftx30ft etc and height usually 6ft about.

The reason of choosing a five axis machining center is because of its professional processing capabilities. It has a multi axis control system, which can carry out accurate cutting and carving operations in multiple directions, making the foam models produced with higher precision and complexity.

By using the five axis machining center to make the yacht foam model, the designer can realize all of the creativity and requirements in his mind, and the production efficiency and precision can be improved at the same time also.

The general process of making boat/ship/yacht foam model with 5 axis machining center is as follows:(how to build a ship model properly )

1. Design model:

firstly, a design drawing or CAD file of yacht foam model is required. This can be done by designers or engineers.

Usually we advise Powemill software with post processer to make design and output working toolpath, this machine control system is PLC Syntec 610w-E5 with separate control panel,same as below pic:

2. Preparation materials:

select suitable wood and foam materials, such as polyurethane or polystyrene. These materials are usually supplied in sheets or blocks.

Usually for ship model making it need huge size like 10ft by 20ft/20ft by 40ft and height 10ft .

Below is the foam smaterial for your option.

3. Develop machining path:

Use CAM software to input design drawings into the five axis machining center and develop machining paths. The machining path will guide the movement trajectory of the five axis machining center during the cutting and carving process.

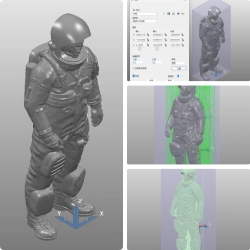

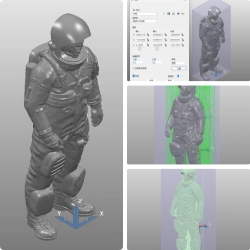

There need proper post processer to do this step and we will offer it to you ,so you no need worry about software problem. Below is the post processer display: (English language is available )

4. Fixing material:

fix the foam material on the ground of the five axis machining center, usually by fixture or glue.

If the 5 axis cnc router have working table, so you can put the material on the machine table and fix it by fixture directly.

Also have vacuum working table for option, but mostly customers consider T-SLOT working table in use.

5. Processing operation:

According to the processing path, start the five axis machining center for cutting and carving operations. The five axis machining center can simultaneously cut and carve in multiple directions to achieve more complex shapes and details.

Below is Rhino 5 axis cnc router machine working video for your option:

6. Completion and cleaning:

after processing, take down the made yacht foam model. Perform surface treatment, trimming, and cleaning as needed to obtain the final model.

It should be noted that the operation of the 5 axis machining center requires skilled operators and with appropriate safety measures. Ensure that relevant operating procedures and precautions are followed during the operation process so can get a safe and high-quality production.

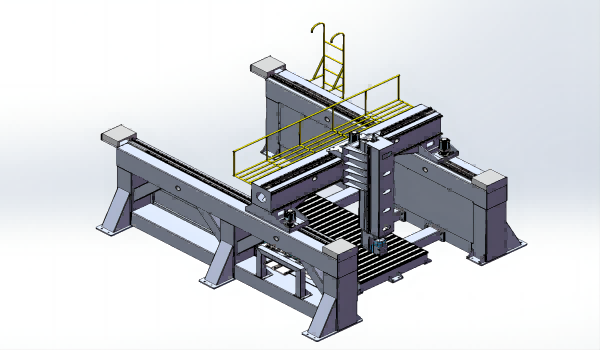

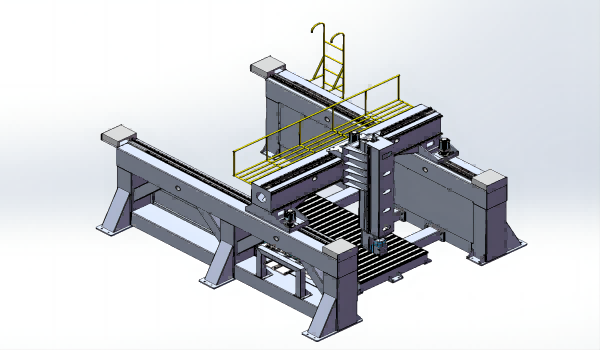

Below are some popular 5 axis cnc router machine produced by Rhino CNC that recommended to you:

1. Rhino DAMES 5 Axis CNC Router Woodworking for 3D Mold Sculpture Making

2. Rhino CNC Router 5 Axis for Wooden Foundry Mold And Pattern Making

When talking about ship /boad/yacht models, many people will think of such models like decoration or hand-made models small size.

In fact, there is also a ship model in the manufacturing industry with big size, which is mostly processed with foam and wood. Today we are talking about this type of boat models.

This boat ship model or yacht foam model is mainly processed by a 5 axis machining center. Yacht foam models are usually made of foam materials such as polyurethane or polystyrene, which can be cut and carved through a 5 axis machining center.

And this kind of models usually dimension is big like 5ftx10ft/20ft x 40ft/10ftx30ft etc and height usually 6ft about.

The reason of choosing a five axis machining center is because of its professional processing capabilities. It has a multi axis control system, which can carry out accurate cutting and carving operations in multiple directions, making the foam models produced with higher precision and complexity.

By using the five axis machining center to make the yacht foam model, the designer can realize all of the creativity and requirements in his mind, and the production efficiency and precision can be improved at the same time also.

The general process of making boat/ship/yacht foam model with 5 axis machining center is as follows:(how to build a ship model properly )

1. Design model:

firstly, a design drawing or CAD file of yacht foam model is required. This can be done by designers or engineers.

Usually we advise Powemill software with post processer to make design and output working toolpath, this machine control system is PLC Syntec 610w-E5 with separate control panel,same as below pic:

2. Preparation materials:

select suitable wood and foam materials, such as polyurethane or polystyrene. These materials are usually supplied in sheets or blocks.

Usually for ship model making it need huge size like 10ft by 20ft/20ft by 40ft and height 10ft .

Below is the foam smaterial for your option.

3. Develop machining path:

Use CAM software to input design drawings into the five axis machining center and develop machining paths. The machining path will guide the movement trajectory of the five axis machining center during the cutting and carving process.

There need proper post processer to do this step and we will offer it to you ,so you no need worry about software problem. Below is the post processer display: (English language is available )

4. Fixing material:

fix the foam material on the ground of the five axis machining center, usually by fixture or glue.

If the 5 axis cnc router have working table, so you can put the material on the machine table and fix it by fixture directly.

Also have vacuum working table for option, but mostly customers consider T-SLOT working table in use.

5. Processing operation:

According to the processing path, start the five axis machining center for cutting and carving operations. The five axis machining center can simultaneously cut and carve in multiple directions to achieve more complex shapes and details.

Below is Rhino 5 axis cnc router machine working video for your option:

6. Completion and cleaning:

after processing, take down the made yacht foam model. Perform surface treatment, trimming, and cleaning as needed to obtain the final model.

It should be noted that the operation of the 5 axis machining center requires skilled operators and with appropriate safety measures. Ensure that relevant operating procedures and precautions are followed during the operation process so can get a safe and high-quality production.

Below are some popular 5 axis cnc router machine produced by Rhino CNC that recommended to you:

1. Rhino DAMES 5 Axis CNC Router Woodworking for 3D Mold Sculpture Making

2. Rhino CNC Router 5 Axis for Wooden Foundry Mold And Pattern Making

Recently Reviews

Read MoreLeave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG