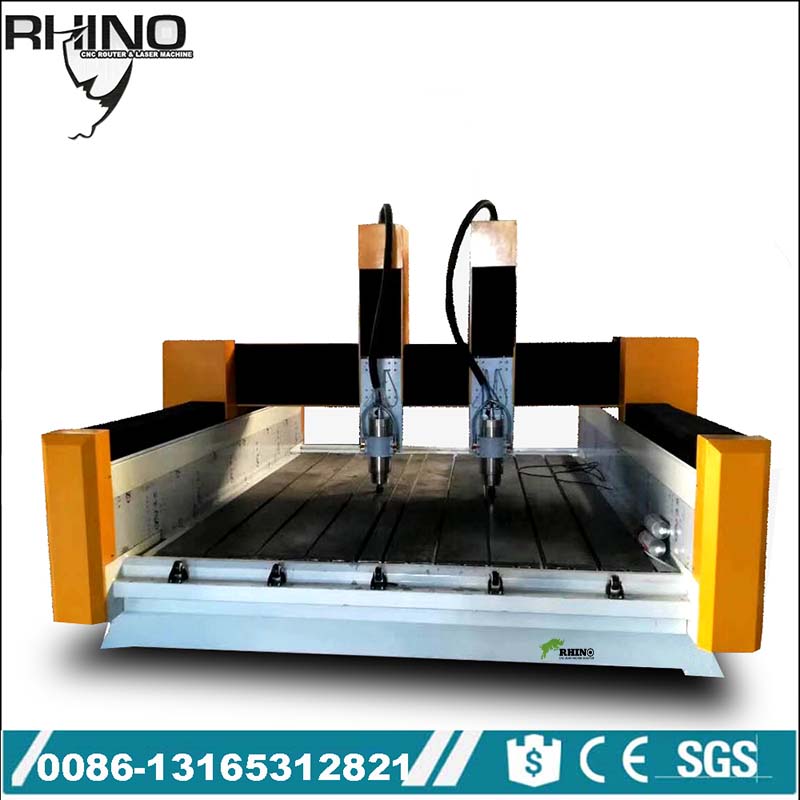

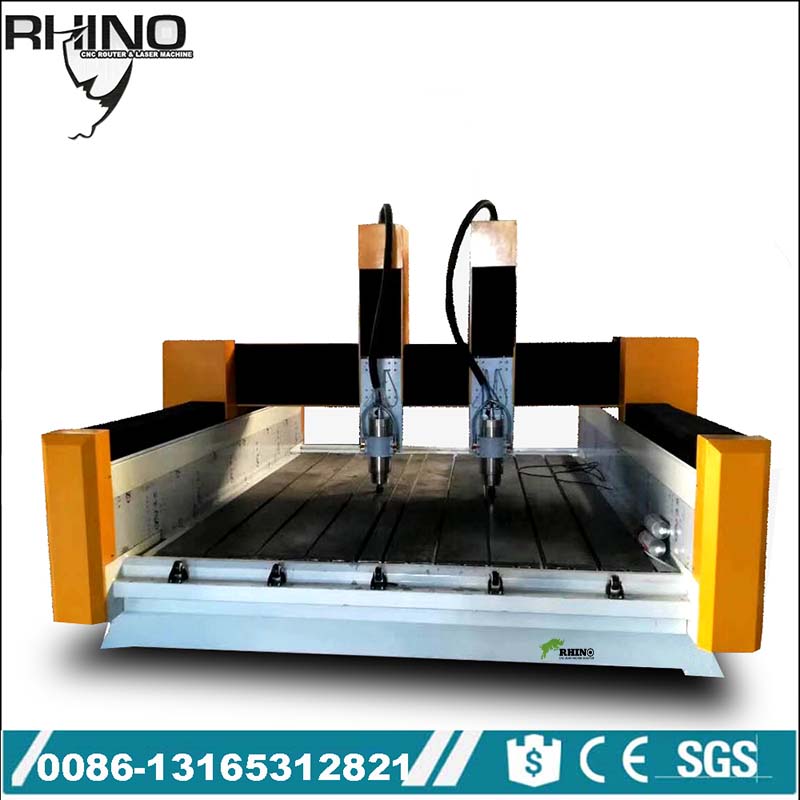

Popular Double Heads Stone Cutting Machine for Marble Granite Glass

This is popular double heads stone cutting machine for marble granite glass,pvc,wood,acrylic ,metal etc

all hard materials same time processing two identical pieces, greatly improving efficiency, suitable for processing relief, lines.

Working materials of stone cutting machine R-1530D

This machine can work all kinds of materials like Artificial stone, quartzite, marble, granite, sandstone, bluestone, cement, tile etc.

Application area of stone cutting machine R-1530D

Stone industry, advertising industry, woodworking industry, craft gifts, building model, electronics, CAD / CAM industrial mold industry, decoration, clothing, packaging and printing, printing and dyeing, logo, etc

More instruction of stone cutting machine :

1. The driving motor is responsible for the power output of the engraving machine in all directions. There are four common types: stepping motor, hybri d servo motor, domestic servo motor and imported servo motor.

we suggest that customers suggest the servo motors. Also stepper motor is no problem for stone engraving machine.

2. Precision machining of machine:means the parts which need to be processed with high precision. For example, lathe, milling machine, drilling machine, planer, double arm planer, machining center, etc.

3. Heat treatment:machine underframe, gantry, head components, etc. if they are not treated after welding, the machine will deform with time, and the longer the time is, the larger the deformation will be. Heat treatment process is to eliminate and reduce this deformation.

4. Water tank.:The machine uses circulating water to spray water for tools cooling. The water tank is the place where water is stored. Rhino company use stainless steel material water tank in machine.

5. Machine Table:it is the place where stone workpieces are placed on the machine. There are many kinds of designs for the table top, such as soft PVC on the aluminum profile plate, super hard polyester plate inlaid with aluminum profile strip, super hard polyester plate fixed on the channel steel table top, and super hard polyester plate fixed on the hollow table top, etc. Channel steel table and hollow table are convenient for machine tool cleaning, which is Rhino cnc company used in this stone cnc carving machine.

6. The common materials of the platform panel are soft PVC and super hard polyester board. Soft PVC is easy to be damaged, which affects the processing flatness. we use super hard polyester board.

7. Control card, which is the brain of the whole stone carving machine, reads the analysis programming file and outputs the processing signal. All the movements on the machine tool originate from the signals output by the control card.

Features of double heads stone cutting machine R-1530D

1.The bed is made of thick wall steel pipe by welding. After high temperature tempering treatment, the deformation of the body is small, the rigidity is good and the strength is large.

2. Y-axis is driven by double motors, matched to ensure smooth movement.With reducer motor to make sure working more stronger.

3. High precision rack and pinion drive is adopted, with high precision, high speed and great power.

4. It adopts imported square linear guide rail, with high precision, large load-bearing redundancy and long service life.

5. All mechanical and electrical design, select a variety of electrical accessories, reduce the failure rate.

6. The machine is equipped with water tank and automatic water supply cooling system.

7. All dustproof and waterproof design, all-round protection of machine transmission parts

8. Optimize technology of frequency conversion to save 10 kilowatt hours per day.

9. The carving depth of one layer is up to 15 cm, and the speed is increased by 100 times.

10. Simple operation makes carving easier.

11. Automatic leveling, uneven stone can be engraved with flat words.

12. Special spindle which can work on all kinds of materials like hard stone, glass, metal etc

Detail technical specifications:

| Model |

R-1530D |

| Working size |

1500*3000*400mm |

| Table size |

1580*3550mm |

| Body structure |

Steel structure |

| Working table |

T-SLOT |

| Working accuracy |

±0.05mm |

| Repositioning accuracy |

±0.05mm |

| Traveling speed |

40m/min |

| Working speed |

25m/min |

| Spindle |

Double water cooling spindle 5.5KW HQD |

| Spindle rotary speed |

0-24000rpm |

| Control system |

Ncstudio/dsp/nk105 |

| Drive and motor |

Servo motor drivers 850w |

| Transmission mode |

Gear wheel for XY axis Original HIWIN20 square rail, TBI 25mm ball screw for Z axis HIWIN20 square rail |

| Working voltage |

AC380v 3 phase |

| Command language |

G-code,*u00,*mmg,*plt |

| Software |

Artcam |

| Cutters |

10 pieces with diameter of 6 and 12.7 |

| Tool Calibrator |

Included |

| Dust collector |

Without |

| Oiling system |

manually oiling |

| Machine weight |

1800kg |

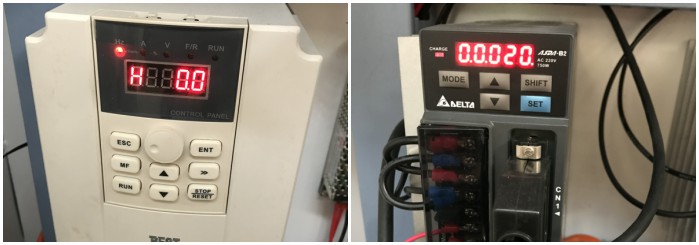

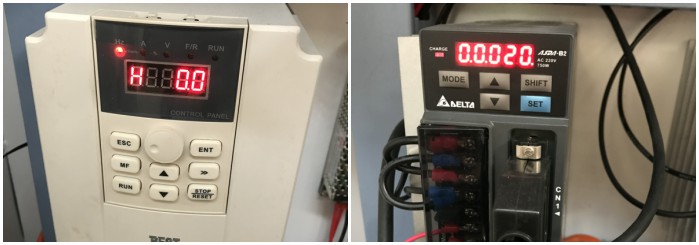

| Inverter |

Delta brand |

| Packaging Measure |

180cm*220cm*180cm |

Machine detail components:

1. Best/Delta brand inverter 2. Servo motor and drivers 850w and motor with reducer motor

3. Double heads water cooling 5.5kw spindle which is professional for stone working 4 bearings inside long time working no problem

4. New tyle clapms 10 sets together offer to you with machine in tool box

Cutting and engraving samples:

How we package and delivery this machine?

Firstly machines are inspected by engineers make sure no any problem then we have special workers who are professional for machine pacakge. We use plastic film cover machnes to avoid moisture on the sea then we use strong stap to tight machine all components well like gantry,table,dust collector and control panel etc

Firstly machines are inspected by engineers make sure no any problem then we have special workers who are professional for machine pacakge. We use plastic film cover machnes to avoid moisture on the sea then we use strong stap to tight machine all components well like gantry,table,dust collector and control panel etc

Then we will move it on the plywood bottom bracket. Setting it in the proper location then use air nail to fix machine legs well on the bracket. It will take about 1-2 hours then we make a full package with plywood box. Finally we use steel strap tight the whole plywood box and print shipping mark and something else as per customer requirement on outside of box. Now the whole process is finished well and it will take 2-3 hours to package it.

Then we will move it on the plywood bottom bracket. Setting it in the proper location then use air nail to fix machine legs well on the bracket. It will take about 1-2 hours then we make a full package with plywood box. Finally we use steel strap tight the whole plywood box and print shipping mark and something else as per customer requirement on outside of box. Now the whole process is finished well and it will take 2-3 hours to package it.

Welcome to contact us for more details about this stone cutting and engraving machine !

Welcome to contact us for more details about this stone cutting and engraving machine !